On-site service for Unterweser nuclear power plant

The E.ON Unterweser nuclear power plant are one of the customers that take advantage of the services available in our modular TotalSealCare portfolio. The range of services includes seal cutting on site, seal procurement and delivery, measurement and generation of seal system drawings.

Read the complete case study...

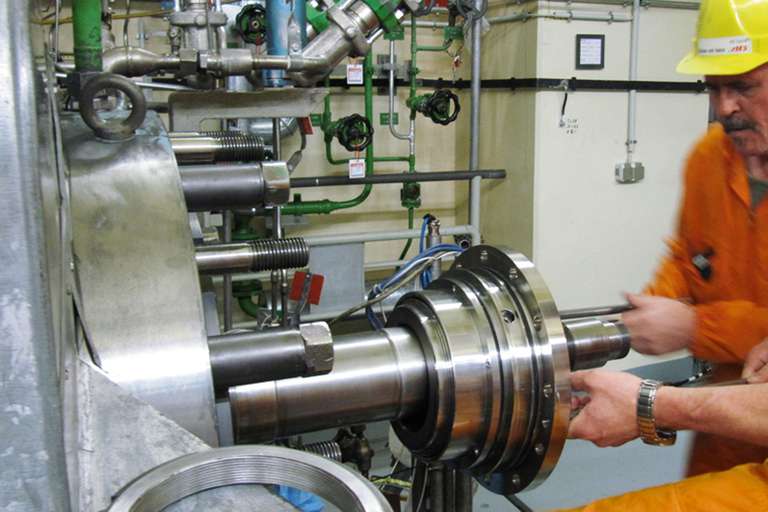

Shaft seal for reactor circulation pump

An EagleBurgmann HSV9/142-Ta1 mechanical seal is installed on a KSB reactor circulation pump at Vattenfalls Krümmel nuclear power plant in Germany.

Operating conditions: p = 71 ... 90 bar (1,030 ... 1,305 PSI), t = 40 °C ... 60 °C (104 °F ... 140 °F), n = 2,000 min-1.

Magnetic coupling for condensate pumps

EagleBurgmann 22P-10R-40-SC2 HE magnetic couplings are installed at the Gösgen nuclear power plant in Switzerland. They are installed on four Sulzer (TMCM 200-400) pumps which circulate condensate in the cooling loop. The huge startup torque (1,120 Nm) is transferred very efficiently to the hermetically sealed system loop.

Operating conditions: p = 26 bar (377 PSI), t = 185 °C (365 °F).

Shaft seal for high-pressure feed pump

At the Olkiluoto (Block 3) nuclear power plant in Finland, a CVCS high-pressure feed pump which circulates radioactively contaminated reactor water must be absolutely reliable. An SHFV-D4-/77-E1-Q mechanical seal is used in this application.

Operating conditions: p = 181 bar (2,625 PSI), t = 15 ... 100 °C (59 °F ... 212 °F), n = 2,980 min-1.

Espey shaft seals for valves

On a valve which closes isolation flaps in an emergency at the Olkiluoto (Block 3) power plant in Finland, an Espey WKA600S carbon ring floating seal with leakage drain is used to seal off the steam.

Operating conditions: p = 11.6 bar (168 PSI), t = 311 °C (592 °F).

Shaft seal for fuel pool cooling pump

A reliable sealing solution for borated water was needed on a Sulzer fuel pool cooling pump at Olkiluoto (Block 3) in Finland, which is Europe's most modern nuclear power plant. The solution which was deployed is an H75VN/95-E5-Q mechanical seal.

Operating conditions: p = 6 barg (87 PSIG), t = 7 ... 110 °C (45 °F ... 230 °F), n = 1,460 min-1.

Mechanical seal for vertical pumps

Sixteen model TXR type BJ3X4X11 Sulzer single-stage vertical reheater drain pumps were equipped with the newly designed SHFV1/42-E1 seal type to overcome the severe cooling problems caused by high temperatures and pressure. The seals have performed excellently since start-up and operate to the complete satisfaction of the customer.

Read the complete case study...

Shaft seal for main feedwater pump

In a German power station, the shafts of the main feed pumps are sealed with EagleBurgmann type DF-SAF1/165 mechanical seals with DiamondFace coating.

Operating conditions: p = 20 bar (290 PSI); t = 184 °C (363 °F); n = 5.730 min-1.

Shaft seal for evaporator concentrate pump

At RWE's Emsland nuclear power plant in Germany an evaporator concentrate pump for radioactive waste is sealed with a RKS2-DF/42-G11-E1-Q mechanical seal.

Operating conditions: p = 3.6 bar (52 PSI), t = 110 °C (230 °F), n = 2,830 min-1.

Diamond-coated mechanical seals

The Exelon Quad Cities Nuclear Station in the U.S. uses Pacific pumps as reactor feed pumps. The reactor feed water is sealed by an EagleBurgmann type DF-SAF5/133-ET1 mechanical seal.

Operating conditions: p = 31 bar (450 PSI); t = 281 °C (538 °F); n = 4.500 min-1.

Diamond-coated mechanical seals

The reactor feed pumps of the nuclear power station in Leibstadt, Switzerland, are sealed successfully with EagleBurgmann DF-SAF5/165.

Operating conditions: p = 35 bar (508 PSI); t = 28 °C (82 °F); n = 5.125 min-1.